-

Radiation Therapy

-

Radiation Therapy

back

-

Categories

-

Categories

back

-

Detectors

-

Detector Arrays

-

Water Phantoms

-

QA Phantoms

-

Electrometers

-

Software Solutions

-

Categories

- Machine QA

-

Treatment Modalities

-

Treatment Modalities

back

- FLASH Therapy

- IMRT/VMAT

- SRS/SBRT/SRT

- MR-Guided Radiotherapy

- Proton/Particle Therapy

- Brachytherapy

-

Treatment Modalities

- Patient QA

-

Treatment Machines

-

Treatment Machines

back

- C-arm Linacs

- Bore-type Linacs

- SRS Linacs

- GammaKnife

- CyberKnife

- ZAP-X

- TomoTherapy/RadiXact

- Proton Therapy Systems

- MR-Linacs

-

Treatment Machines

-

Radiation Therapy

-

Diagnostic Imaging

-

Diagnostic Imaging

back

- Categories

-

Imaging Quality Control

-

Imaging Quality Control

back

- NORMI RAD/FLU

- NORMI 3D

- X-Check DSA

- NORMI 13

- NORMI MAM digital

-

Imaging Quality Control

-

Patient Dosimetry

-

Patient Dosimetry

back

- DIAMENTOR Systems

- DIAMENTOR C-RS

- DIAMENTOR RS-KDK

-

Patient Dosimetry

-

Acceptance Testing

-

Acceptance Testing

back

- NOMEX Dosemeter

- NOMEX Multimeter

-

Acceptance Testing

-

Treatment Modalities

-

Treatment Modalities

back

- Radiography and Fluoroscopy

- Mammography

- Computed Tomography

- Dental Radiography

- X-Ray Radiation Therapy

- Cone-Beam CT

-

Treatment Modalities

-

Diagnostic Imaging

-

Radiation Monitoring

-

Radiation Monitoring

back

- Electrometers

- Ionization Chambers

- Survey Meters

- Personal Dosemeters

-

Radiation Monitoring

- OEM

- Metrology

Product Highlights

BEAMSCAN

Water Phantoms

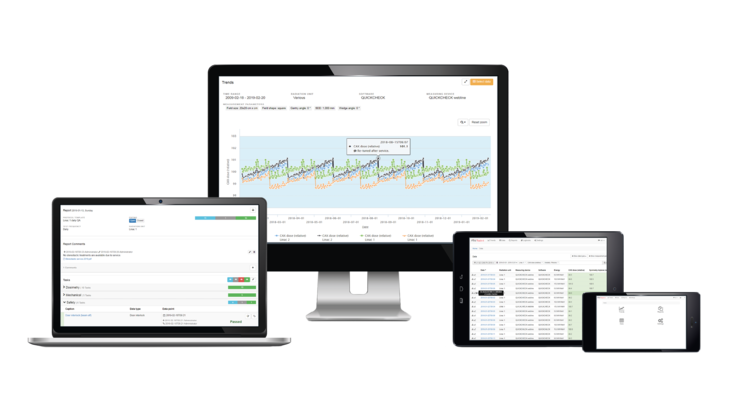

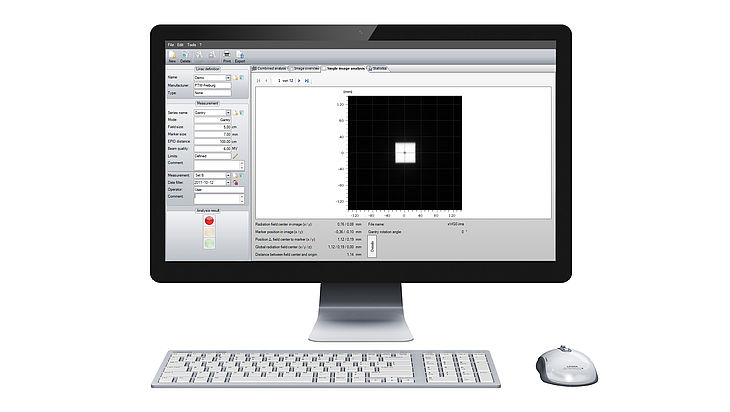

UNICHECK

Web-based Daily QA

VERIQA

Patient QA Platform

RUBY

Modular QA Phantoms

BEAMSCAN MR

Water Phantom for MRgRT

OCTAVIUS 4D / 4D MR

QA Phantom

Electron Density Phantom

Classical Shape Phantom

Track-it

QA Data Management Platform

flashDiamond

Detector

UNIDOS Tango & Romeo

Reference Class Electrometers

Product Highlights